Introduction

Supply chain management plays a critical role in ensuring the seamless flow of goods and services from production to consumption. However, traditional supply chain practices often face challenges such as inefficient inventory management, inaccurate tracking, and delays in logistics. RFID (Radio Frequency Identification) technology presents a revolutionary solution to these challenges, offering enhanced visibility, real-time tracking, and automation capabilities that optimize supply chain operations and drive efficiency.

How RFID Transforms Supply Chains

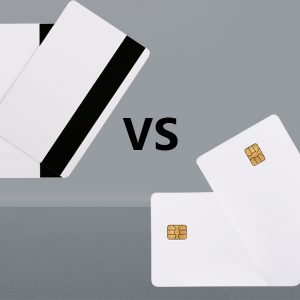

RFID systems consist of tags attached to products or packaging and readers that capture data from these tags via radio waves. Unlike barcodes, RFID Tags Maunfacturer by scanning and can store more information, including unique identifiers and product details. This enables end-to-end visibility into the supply chain, from manufacturing and warehousing to distribution and retail, facilitating seamless tracking and traceability of goods.

Advantages of RFID in Supply Chain Management

The adoption of RFID technology in supply chain management offers numerous advantages. Firstly, RFID enables real-time inventory tracking and monitoring, reducing the risk of stockouts, overstocking, and product obsolescence. By providing accurate, up-to-date information on inventory levels and locations, RFID helps optimize inventory management practices, improve demand forecasting, and enhance overall operational efficiency.

Applications Across the Supply Chain

RFID technology finds applications across various stages of the supply chain, including manufacturing, warehousing, transportation, and retail. In manufacturing, RFID enables automated production tracking, quality control, and asset management, enhancing productivity and reducing lead times. In warehousing and distribution, RFID facilitates efficient inventory management, order picking, and shipment verification, minimizing errors and improving order fulfillment rates.

Future Trends and Innovations

As RFID technology continues to evolve, several trends and innovations are shaping the future of supply chain management. These include the integration of RFID with IoT (Internet of Things) devices, enabling sensor-based monitoring of environmental conditions such as temperature and humidity. Additionally, advancements in RFID reader technology and data analytics tools promise to further enhance the capabilities of RFID systems, driving greater visibility and efficiency across the supply chain.

Conclusion

RFID Tags Maunfacturer represents a transformative force in supply chain management, offering unparalleled visibility, accuracy, and efficiency. By leveraging RFID tags and readers, businesses can optimize inventory management, streamline logistics processes, and improve overall supply chain performance. As the technology continues to advance and become more accessible, embracing RFID-enabled solutions will be essential for businesses seeking to stay competitive and resilient in today’s dynamic global marketplace.